| Sign In | Join Free | My wpc-board.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My wpc-board.com |

|

Brand Name : KUTEDE

Model Number : KTD-090

Certification : ISO

Place of Origin : SHENZHEN CHINA

MOQ : 1Set

Price : Negotiation

Payment Terms : T/T

Supply Ability : 1sets per mouth

Delivery Time : 30 woring days after received the deposit(The actual lead time according to the quantity)

Packaging Details : Accessories packed separately

Size : Customized

PCB Hight : 900±20mm

PCB Direction : L-R/R-L

Product Description

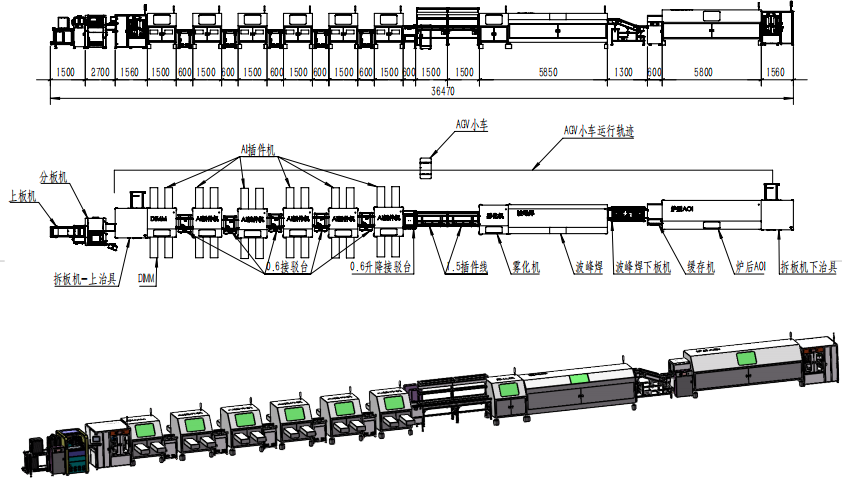

This product is an automated production line covering the entire process of PCB board loading, board separation, multi-machine insertion, soldering, inspection and material cutting. It integrates core equipment such as board mounting machines, board splitting machines, multiple AI insertion machines, 0.6 connection stations, 1.5 insertion lines, nebulizers, wave soldering machines, wave soldering board removal machines, stud machines, AOI after the furnace, fixtures under the board removal machine, and AGV carts. Through the intelligent control system and AGV carts, seamless multi-link linkage is achieved, completing the fully automated operation of PCB boards from raw material loading to finished product unloading. It is suitable for the production scenarios of electronic component soldering that require through-hole processes, ensuring the precision of through-hole insertion and soldering quality while realizing intelligent material scheduling and large-scale efficient production.

Product advantages

Multi-ai insertion machines + AGV intelligent collaboration: Multiple AI insertion machines operate in parallel, and AGV carts achieve intelligent cross-regional material scheduling. The efficiency of insertion and material flow is 80% higher than that of traditional production lines, meeting the mass production requirements of large-scale insertion type PCB boards.

Full-process process integration + intelligent inspection: Integrating the processes of component board, insertion, welding and inspection, AOI at the back of the furnace enables full inspection of defects after welding. The AI insertion machine is equipped with visual recognition technology to ensure high-precision quality control in the insertion and welding stages.

Flexible production + intelligent scheduling: Equipment parameters can be flexibly adjusted according to PCB board specifications and plug-in types. AGV carts support multi-path material transportation and are suitable for flexible production and intelligent scheduling of various types of plug-in PCB boards.

Data-driven production management: Each device is equipped with a data acquisition module, and the AGV operation data is linked in real time with the production line process data, achieving production traceability and process optimization.

Product features

The board loading machine and the board separation machine realize the automatic loading and separation of PCB boards, reducing manual operation.

Multiple AI insertion machines support the insertion of various components, with an insertion accuracy of ≤±0.05mm, and are compatible with DIP components and irregular insertion.

Wave soldering adopts an intelligent temperature control and solder management system, with a soldering yield of ≥99.5%.

The AOI equipment behind the furnace has micron-level detection accuracy, capable of identifying defects such as missing plug-ins, reverse insertion, false soldering, and bridging, with a detection accuracy rate of ≥99.9%.

The AGV trolley has high running accuracy, with a positioning deviation of no more than ±5mm, ensuring the precision of material flow.

Application scenarios

Large-scale PCB board soldering inspection production for through-hole components in the electronics manufacturing industry, such as production lines for industrial control boards, power boards, automotive electronic boards and other products, is particularly suitable for enterprises with high requirements for through-hole efficiency, soldering quality and intelligent scheduling.

|

|

PCB intelligent insertion, soldering and inspection full-process production line (multiple AI insertion machines + wave soldering + post-furnace AOI Images |